Description

During the mining process of mineral resources the elemental composition differs within one or different deposits. The knowledge of the elemental content is of interest for each step within a production process, e.g. the washing process of coal that has to be adapted permanently. At present samples are taken every hour manually and have to be delivered to the laboratory and get prepared. Analytical results can be received after hours sometimes after days. Thus the production process can only be adjusted coarse.

Isa – Online analysis of mineral resources

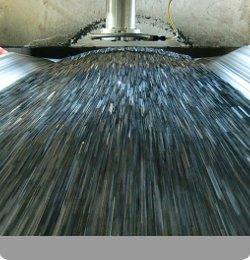

By installing a laser-based measuring system above a conveyor belt where the raw materials are transported with several m/s, a quick response to fluctuations in elemental concentration is possible. Thus, the production steps can be improved by a continous monitoring of the actual state.

Examples are the continouos measurement of ash content of coal, the measurement of the purity of salts or even determining the quality of ore (Fe, Ni, etc.)

- Benefits of Isa:

- Reliable: Isa is a fully automatic, low maintenance testing unit.

- Safe: Isa provides a continious online analysis of mineral resources during minig process.

- Integration: Isa can be integrated into a fully automated production process. The results of the online analysis are available for the production process in real time.

- Non-destructive: By means of the laser supported element analysis, Isa vaporises only the slightest traces of the material.